|

This service is provided with the aim to work in a close, long term partnership, supplying ideas and solutions.

The "Multilink concept" is based on QFD (Quality Function Deployment) methodology not assuming that all knowledge or expertise is under the same roof or in the same room.

Every consultancy is tailored for the specific needs of each Customer:

- Feasibility study - Product's specifications

- Costs analysis - Make or Buy - Lead times

- Product's cost structure - Cost reduction review

|

To order a copy:

ISBN 9780957144705

|

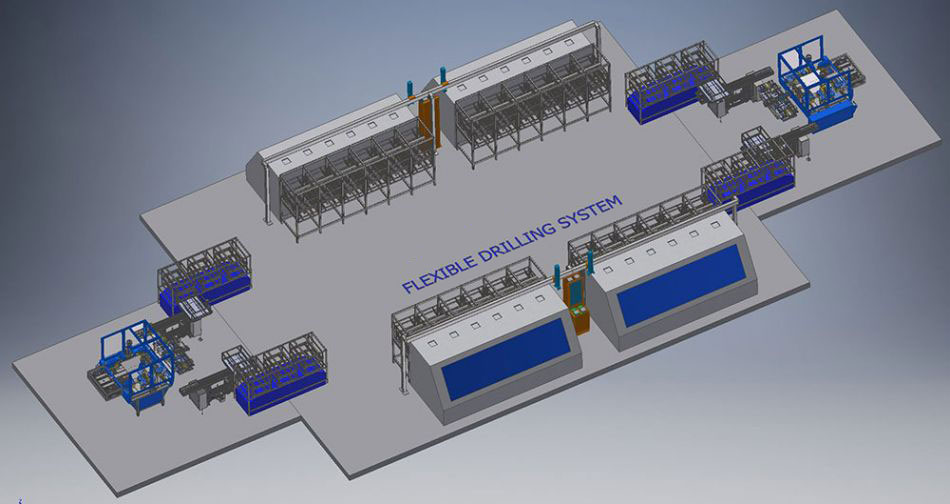

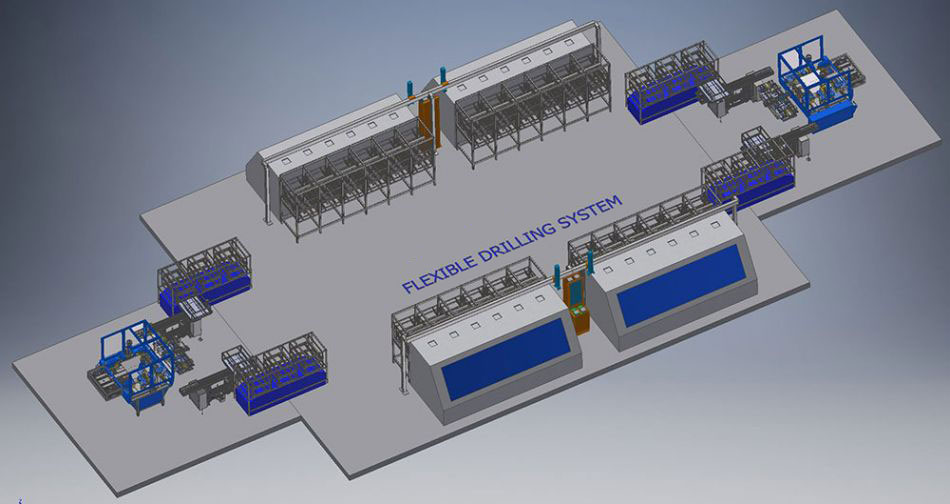

Design it right

Below a design example of a modular Flexible Drilling System:

The system is composed of:

- Stack assembly area with NORTH STAR STACK MASTER

- Precentring station

- Stack Transport system

- Drilling/Pinning/taping core module for Double side or Multilayered Boards

- Automatic pin feed

- Bi-directional out let stations

- Mirror station for stack storage lifts serving 6 levels cages on AGV or Shuttle System

- AGV or Shuttle System capable to carry and deliver to Drilling/Routing Machines loaded cages

- Rear Cage storage Loader/Unloader units to Drilling and Routing Machines

- AGV/Shuttle systems handling cages filled with drilled stacks on delivery to:

- De-pinning / De- Taping Stack Master core module unit complete of out let station to Customer Stack sorting unit ( solution to be customized upon requirements )

- Tool Cassette full automation Center complete with Inlet / outlet drawers

- Tool cassette automation center capable of storing up to 24 cassette with euro magazines.

- Gantry system serving two Drilling machines

Cell controller managing all resources of FLEXIBLE DRILLING CELL including:

- Production program CNC part list

- Automatic calculation of resources needed ( Tools-Parts program- machining times - auxiliary cycle times- queue management for machine allocation )

- Production reports including batch transit time, tool usage, etc

|

Our Engineering Design Services are always offered with detailed costs estimates